Sustainable Manufacturing: Closed-Loop Recycling in Auto Production

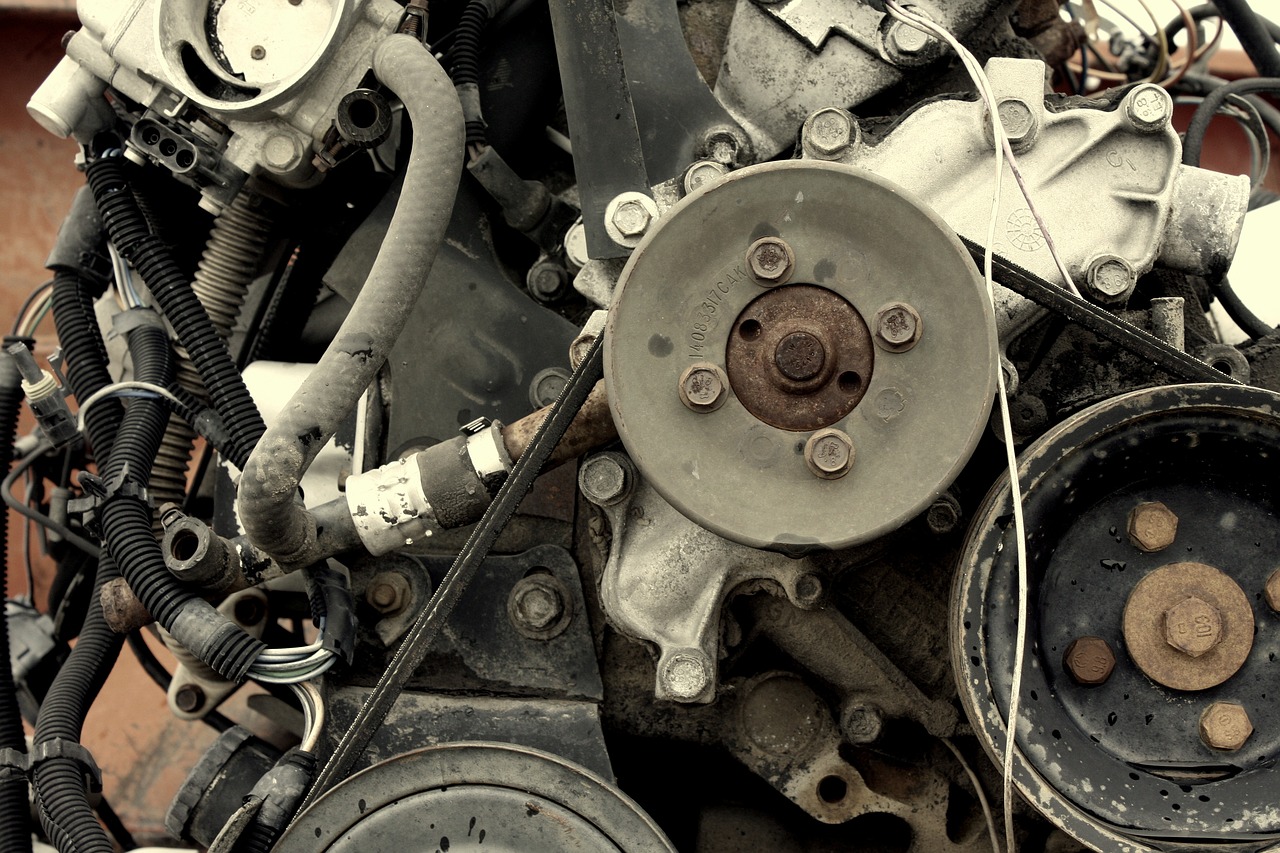

Closed-loop recycling plays a crucial role in the sustainability efforts of the auto industry. By implementing closed-loop recycling processes, manufacturers can significantly reduce the environmental impact of auto production. This approach involves collecting post-consumer materials like old vehicles or scrap metal, breaking them down into raw materials, and then using these materials to create new auto parts.

Not only does closed-loop recycling help to conserve natural resources, but it also minimizes the amount of waste generated during the manufacturing process. This leads to a more efficient use of materials and energy, ultimately contributing to a more sustainable and eco-friendly auto production cycle. Embracing closed-loop recycling practices is essential for reducing the industry’s carbon footprint and moving towards a more environmentally responsible future.

Challenges Faced in Implementing Closed-Loop Recycling in Auto Manufacturing

Implementing closed-loop recycling in auto manufacturing poses various challenges that can hinder its widespread adoption in the industry. One major obstacle is the complexity of the supply chain, as it involves multiple stakeholders such as suppliers, manufacturers, and recyclers. Coordinating these different entities to ensure the seamless flow of materials back into the production process can be a daunting task that requires careful planning and collaboration.

Another challenge faced in implementing closed-loop recycling is the cost associated with setting up the necessary infrastructure and technologies. Investing in recycling facilities, waste sorting systems, and material processing equipment requires a significant upfront capital investment, which may deter some companies from fully committing to closed-loop recycling initiatives. Additionally, the variability in material quality and availability from recycled sources can introduce uncertainties into the manufacturing process, making it challenging to maintain consistent product quality and performance.

Benefits of Closed-Loop Recycling for the Environment

Closed-loop recycling in auto manufacturing plays a crucial role in promoting environmental sustainability. By reusing materials like metals, plastics, and rubber, this process reduces the demand for extracting new resources, conserving natural habitats, and lowering greenhouse gas emissions associated with traditional mining and manufacturing practices. This closed-loop approach helps to minimize waste generation and landfill usage, contributing to a cleaner and healthier environment for present and future generations.

Furthermore, closed-loop recycling lessens the environmental impact of auto production by decreasing energy consumption and reducing pollution levels. The use of recycled materials in manufacturing processes requires less energy compared to extracting and processing raw materials, leading to lower carbon emissions and a smaller ecological footprint. By embracing closed-loop recycling initiatives, the auto industry can actively participate in addressing climate change and fostering a more sustainable future for the planet.

What is closed-loop recycling?

Closed-loop recycling is a waste management strategy where a product is recycled back into the same product, thus creating a circular economy.

How does closed-loop recycling benefit the environment?

Closed-loop recycling reduces the need for raw materials extraction, decreases energy consumption, and minimizes waste sent to landfills, ultimately reducing the carbon footprint of manufacturing processes.

Why is closed-loop recycling important in auto production?

Closed-loop recycling in auto production helps reduce the environmental impact of manufacturing vehicles by reusing materials such as metal, plastic, and glass, which are commonly found in cars.

What are some challenges faced in implementing closed-loop recycling in auto manufacturing?

Some challenges include the cost of setting up recycling infrastructure, ensuring the quality of recycled materials, and coordinating with suppliers to collect and process recyclable materials.

How does closed-loop recycling contribute to sustainability efforts in the automotive industry?

Closed-loop recycling promotes resource conservation, reduces greenhouse gas emissions, and supports the transition towards a more sustainable and circular economy in the automotive sector.